|

By: John Miebers Maintaining profits and keeping jobs on track is not easy in the construction industry. There are bills to pay, materials to order, teams to manage and everything else in between. That’s why you need accurate, real-time Work in Progress (WIP) reports to keep projects running smoothly—and to grow your bottom-line profit. Work in Progress (WIP) is an essential part of construction accounting. It calculates the progress of all ongoing work, allowing you to see what’s been done and what’s left to do—helping you manage budgets effectively. This information can then be used to generate reports and track project development using “percentage complete” figures. Be sure to click the red subscribe button above to receive your digital copy.

By: Tracy Bennett The correlation between physical and mental health is a topic worth discussing as the construction industry faces high suicide and substance use disorder rates. A recent article published by Conexpo-Con/Agg quoted Carol Nixon, PhD, research health scientist, NIOSH Spokane Mining Research Division. She said: “Manual labor increases risk of work-related injuries and strain; and pain is the most common reason for receiving an opioid prescription. Opioids are extremely addictive. It can take just five days to become addicted.” “The high rates of substance use disorder and overdose in industries like construction and mining are not an indictment of the workers who take these jobs,” Nixon says. “Rather, this is an urgent call to identify workplace factors that may contribute to these devastating outcomes and how those may be modified to prevent illness, injury and death and promote employee health and well-being.” Be sure to click the red subscribe button above to receive your digital copy.

Be sure to click the red subscribe button to receive your digital copy.

Be sure to click the red subscribe button to receive your digital copy.

By: Todd Alwood Quality control is not just about plans and processes. It’s also about where the rubber meets the road, or in the case of steel fabrication and erection, where the arc meets the metal. If there’s one thing we know about training, it’s that actually doing something is more effective than talking about it. We can talk about how helping your staff develop their skills–investing in their success as an individual–cuts down on attrition. We can talk about how important it is that everyone on a team knows what their quality management system does and how it works. But doing is more effective than talking–and people who do it know more than people who talk about it. The seven people you’ll meet here do steel construction quality training on a regular basis. Every shop or jobsite is different, but these lessons have broad applicability. Read on for their tips, tricks, and lessons learned. Be sure to click the red subscribe button above to receive your digital copy.

By: Michael Brady and Jeremy DeGrande Construction in manufacturing and infrastructure remains strong, while the commercial sector is lagging, according to Engineering News-Record’s 2023 2Q survey of its Top 400 Contractors. And despite the Federal Reserve’s efforts, respondents reported concern regarding the general economic outlook. However, contractors remain busy — many report a higher-than-normal backlog of projects and demand for their services. These conditions add up to a competitive construction market with some unprecedented stressors. Current market conditions ENR surveyed construction executives between May 15 and June 26 and published its report in July 2023. Using the results, the publication rated the current market outlook a 40 on its 100-point Construction Industry Confidence Index, which quantifies how confident these executives feel about the state of the market now, in three to six months, and in 12 to 18 months. This rating is down four points from the previous quarter. Be sure to click the red subscribe button above to receive your digital copy.

By Tracy Bennett In the last three years, SEAA has tripled its benefits programs and doubled in-person networking events. “By offering more opportunities for our members to connect and the chance to tap new hiring, training, and business resources, we are giving contractors the tools they are seeking to better run their businesses,” said R. Pete Gum, Executive Director. The average membership fee is $1,640, while the value of services available to members is greater than $30,000 annually. “Whether you are already a member, but not taking full advantage of the resources available to you, or you are not yet a member, this information is for you,” said Jack Nix, Chief Operations Officers for Shelby Erectors and Chairman of the Membership Committee. Shared connections Every association says the primary benefit of participation is the networking, but members of SEAA say it best themselves. SEAA holds an annual Convention & Trade Show that rotates between east and west locations. The 2024 event is April 2-5 in Glendale, Arizona. Other opportunities to meet include regional Meet & Greet receptions and Peer Group discussions that take place in conjunction with summer, fall, and winter Board of Directors meetings held at various locations around the country. The Dave Schulz Memorial Golf Tournament is a fundraiser event held every fall. It also alternates between east and west. “Our company is where it is today because of the networking through SEAA. For 25 years, SEAA has contributed to my personal growth as a business owner and the overall improvement of our company. Other members willingly answer questions pertaining to industry standards, OSHA regulations, subcontract language, and more,” said David Deem, President of Deem Structural Services and President of SEAA (2022-2024). Be sure to click the red subscribe button above to receive your digital copy.

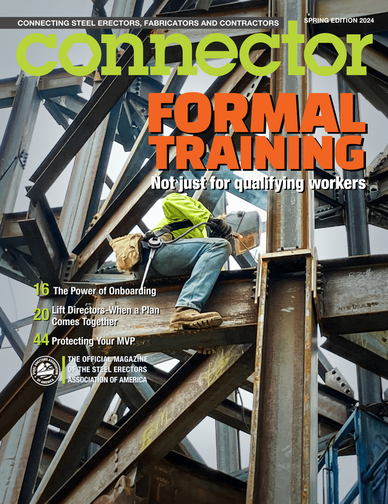

By Tim Neubauer, MS, CSP | JoAnn Dankert, CSP, CHMM, CIT | Kimberly Kemp, PhD In the contemporary workplace, the era of one-sizefits-all instructional paradigms is effectively over. This is particularly the case in complex, high-stakes industries like steel erection. In such fields, training isn’t a mere formality but a crucial process that ensures not only competency but also safety. A misstep or misunderstanding can result in serious injury or even loss of life, making the stakes exceedingly high. In-house trainers can be more effective when they take a comprehensive approach and understand their audience. In the 21st century, steel erection training requires more than rote learning. Workers require a deep understanding and practical application of complex principles, ranging from physics to safety regulations. The risks of getting it wrong are not just financial but can be human as well. With increasing technological complexity and a more diverse workforce, the one-size-fits-all model has become obsolete. Adapting content and delivery Today’s workforce is incredibly diverse, not only in terms of demographic factors like age, ethnicity, and educational background but also in terms of learning styles. According to the Cone of Learning developed by Edgar Dale, the retention rate for different types of educational activities varies widely. For instance, people generally remember only 10% of what they read but as much as 90% of what they do or teach others. Emerging technologies such as augmented and virtual reality offer unprecedented opportunities to adapt training to individual needs and to integrate more hands-on learning. For example, virtual reality scenarios can simulate the high-risk, high-stakes environment of a steel erection project, providing workers with a safe space to practice skills and procedures. A 2020 study by Price Waterhouse highlighted that trainees retained over 80% of the material through virtual reality training, compared to much lower retention rates for traditional methods. Moreover, this kind of training can be completed in a fraction of the time, leading to cost savings and quicker deployment of skilled workers. Be sure to click the red subscribe button above to receive your digital copy.

|

RSS Feed

RSS Feed