|

Image credit: Occupational Safety and Health Administration The clang of steel meeting steel, the hum of heavy machinery, the pop of a powder actuated tool, the scream from a saw, and the roar of construction activity. These are the sounds of the steel erection industry. However, there is a hidden danger: the threat of occupational noise exposure. Recognizing this risk, OSHA has established rigorous standards to ensure the hearing safety of workers. Additionally, modern technology that detects sound decibels, such as sound apps for a smartphone, has become a valuable tool in monitoring and managing noise exposure.

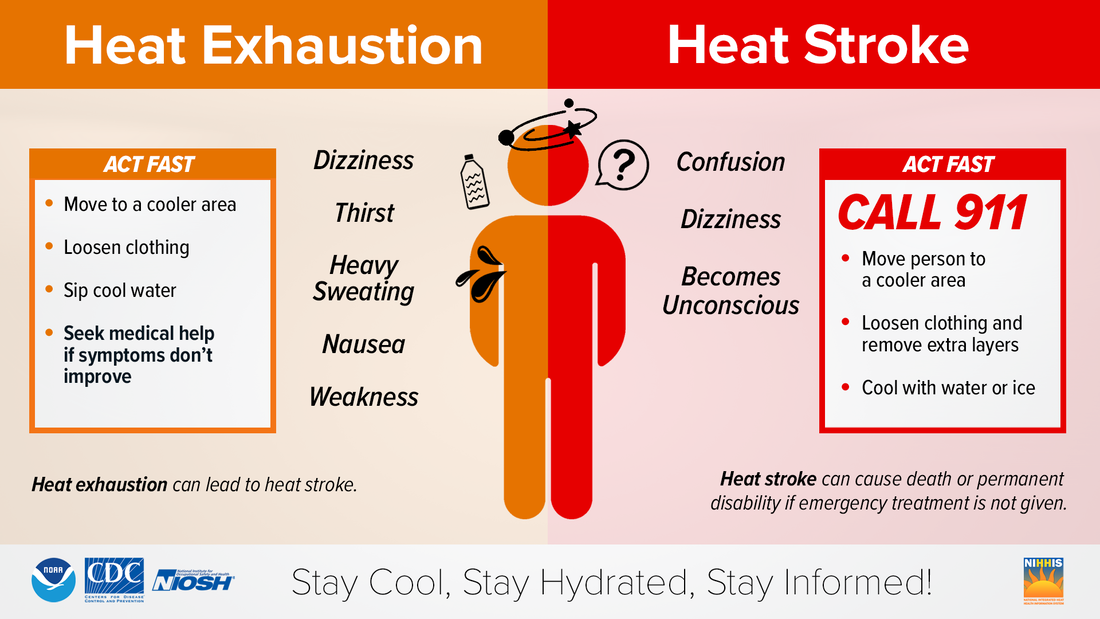

Image source: National Weather Service In steel construction, exposure to high temperatures is common. As we head into the summer months, it’s critical to address the heat stress and the signs of heat related illnesses to ensure the safety and well-being of workers. Recognizing the significance of this issue, the American National Standards Institute (ANSI) and the American Society of Safety Professionals (ASSP) introduced the ANSI/ASSP A10.50-2024 standard. Released on February 26, 2024, this standard provides tips and guidelines for effectively managing heat stress. By understanding and implementing these guidelines, employers and workers in steel construction can mitigate the risks associated with heat-related illnesses and create safer working environments.

ANSI/ISEA Z89.1-2014 (R2019) When you think of a hard hat, what do you picture? Do you picture the shell with a peak, a head band and harness? We have come to know these as the traditional style, or Type 1 hard hat. Type 1 hard hats work well, but what do we see happen when someone falls? We tend to see hard hats come off employees’ heads, especially when there is no chin strap.

Based on ANSI standards, Type 1 hard hats are designed to reduce forces as a result of an impact only to the top of the head. Performance requirements are as follows:

Safe rigging practices are essential for the safety of everyone working near crane activities on a job site. Improper rigging techniques can lead to serious accidents, injuries, and damage to property. There is a wide variety of different rigging methods that can be applied in various lifting scenarios and it’s crucial to have the correct knowledge in selecting the correct method in each case. Rigging for steel erection presents unique challenges. Read on for best practice reminders on inspection, selection, and communication. Inspection and training

First and foremost, employees need to ensure that all rigging equipment is inspected and maintained regularly. This includes wire rope, chains, nylon, polyester, hooks, and other hardware used for lifting and moving loads. Any equipment showing signs of wear such as, cuts, abrasions, severe wear, broken wires, cracked fittings, chemical burns, UV damage and distortion should be immediately taken out of service and replaced. Regular inspections and maintenance help to prevent equipment failure and ensure that all rigging gear is in good working condition. Proper training for riggers is another critical aspect of safe rigging practices. Workers involved in rigging operations need to receive comprehensive training on the safe use of rigging equipment, as well as the identification of potential hazards and proper procedures for lifting and moving loads. Additionally, workers should be trained to understand load capacities, weight estimation, center of gravity, and the importance of balancing and securing loads to prevent accidents. Employers should also keep their employees training fresh as new standards, practices, rigging hardware is always changing.  When it comes to roof integrity, one component that plays a crucial role is the K-series bar joist. These structural members provide essential support and stability to the roof system, ensuring its durability and performance. In this blog post, we will explore the importance of K-series bar joists and their contributions to maintaining roof integrity. K-series bar joists are lightweight, open-web steel trusses that are commonly used in commercial and industrial construction. They consist of top and bottom chords connected by diagonal web members, forming a triangular truss pattern. These joists are designed to span long distances, providing structural support for roof decks and accommodating various load requirements. One of the primary functions of K-series bar joists is to bear the weight of the roof system and any additional loads applied to it. The load-carrying capacity of these joists is determined by their design, size, and spacing. By distributing the weight evenly across the joist system, K-series bar joists prevent excessive deflection and ensure that the load is transferred to the supporting columns and walls. This contributes significantly to the overall stability and integrity of the roof structure. Integration with Roof Decking and Roofing Systems The K-series bar joists seamlessly integrate with roof decking and roofing systems, and the open-web design allows for the easy installation of roof deck materials, such as metal panels or concrete slabs, between the joists. This integration enhances the overall performance of the roof, providing a secure and stable platform for the roofing materials. The compatibility of K-series bar joists with different roofing systems ensures a harmonious and efficient construction process.  Fire safety is a critical consideration in roof design, and K-series bar joists offer inherent fire-resistant properties. The open-web design allows heat to dissipate more effectively, minimizing the risk of structural failure during a fire event. Additionally, the use of fire-resistant coatings or insulation materials can further enhance the fire resistance of K-series bar joists, ensuring the safety of the building occupants and preserving the roof's integrity. The lightweight design reduces material costs and allows for faster and more efficient installation. The long-span capabilities of these joists reduce the need for additional support columns, maximizing the usable space beneath the roof. Moreover, the prefabricated nature of K-series bar joists enables streamlined construction processes, saving time and labor costs. These are essential components in maintaining roof integrity and ensuring the longevity of commercial and industrial buildings. With their load-carrying capacity, design flexibility, integration with roof decking and roofing systems, fire safety features, and cost-effective construction advantages, these joists provide the structural support necessary for a robust and reliable roof system. By understanding the importance of K-series bar joists and collaborating with knowledgeable professionals, architects, engineers, and contractors can create roofs that are not only aesthetically pleasing but also structurally sound and built to last. Read the original article from Oates Metal Deck and Building. This Safety Flash was contributed by Oates Metal Deck and Building Products, in cooperation with SEAA’s Safety & Education Committee. It’s designed to keep members informed about ongoing safety issues and to provide suggestions for reducing risk. Best practices are gathered from a variety of sources. They may be more or less stringent than individual corporate policies and are not intended to be an official recommendation from SEAA. Always get approval and direction from your company officers on any new practice or procedure as these best practices may not work for all situations.

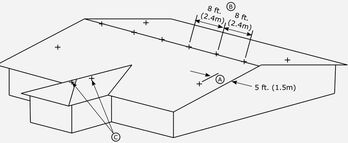

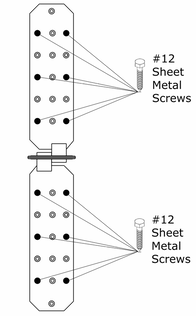

Everyone benefits when a worker avoids injury. Submit your ideas for Safety Flash to [email protected].  Whether you're a steel erector or a metal decking company, a butterfly roof anchor is a common choice for decking activities and accessing work areas, but there can be a catch. It’s critical to choose the right roof anchor because some are specifically designed for residential wood structures installed on the peak of the roof and NOT for steel erection or metal decking. After ANSI Z359.18-2017 was approved in August 2017, manufacturers’ product development teams started looking at the new rigorous anchor requirements. Even though the butterfly is an OSHA rated anchor, it is still a single user anchor, which is now deemed necessary for fastening through decking and purlin to ensure proper strength. Manufacturers updated their user manuals to reflect the changes but there was no memo to reflect the change from some manufacturers. Steel erectors and decking companies still had the old user manual stating screws did not have to penetrate a structural member underneath deck sheet. Before you get stuck with the wrong anchor, let's dive into the details. Know the Regulations OSHA's Subpart 1926.758(g) states that purlins and girts can't be used as anchorage points for fall arrest systems without written approval from a qualified person. So, before putting any system into use, make sure to submit a letter of override to ensure you're complying with safety standards and not compromising the structural integrity of the steel purlins.  Review Product Materials and Manuals The hinged roof anchors from major fall protection equipment manufacturers like Fall Tech, Safewaze, and 3M are often referred to as butterfly roof anchors and can be used on metal deck sheets in pre-engineered buildings with z-purlins. Falltech's Engineering Manager, Zack Winters, emphasizes that their model #7410 anchor can withstand a 5000 lb. load when fastened properly to a minimum 20-gauge steel deck. Just make sure to use the recommended fasteners and follow the installation instructions. Safewaze and 3M user manuals state a minimum 22-gauge metal roofing/decking over minimum 16-gauge Z-purlin. Fall Tech is the same with the exception of minimum 14-gauge Z-purlin instead of 16-gauge.  But what about different types of deck sheets? For floor deck sheets, which are usually 18-gauge, you’ll need to fill in the screw holes to prevent concrete leakage. And when it comes to commercial or industrial roof deck sheets, typically 22-gauge, the butterfly roof anchors won’t work on top of them alone. However, research shows that all three manufacturers allow screwing the butterfly anchor into a structural member underneath the deck sheet, such as a purlin. Other Considerations Installation manuals don’t provide information on anchoring butterflies to metal decking over steel bar joists or I-beams. You’ll need to assess the structure’s components, sheet gauge, purlin size, and availability to find the best anchor solution. And remember, an anchor system installed using columns or overhead can eliminate holes in deck sheets and purlins, providing greater fall distance clearances and less paperwork hassle with OSHA. So, next time you're choosing a roof anchor, keep these insights in mind. Safety first! References: DBI Sala, User Instruction Manual Hinged Roof Anchor Model Number: 2103676 Fall Tech, Metal Frame Structure Anchor 7410M User Instruction Manual Supplement Occupational Safety and Health Administration. (1970). Occupational safety and health standards: Occupational health and environmental control (Standard No. 1926 Subpart R) Safewaze, FS870 / FS870N / FS870S Reusable Roof Anchor Winters, Frost, July 31, 2019, #7410 Anchorage Connector in Metal Deck Applications, Fall Tech This Safety Flash was contributed by, Jeremy McAllister, Safety Director for Gardner-Watson, in cooperation with SEAA’s Safety & Education Committee. It’s designed to keep members informed about ongoing safety issues and to provide suggestions for reducing risk. Best practices are gathered from a variety of sources. They may be more or less stringent than individual corporate policies and are not intended to be an official recommendation from SEAA. Always get approval and direction from your company officers on any new practice or procedure as these best practices may not work for all situations.

Everyone benefits when a worker avoids injury. Submit your ideas for Safety Flash to [email protected].  Torque wrenches deliver the power and accuracy required to tighten nuts and bolts while preventing structural damage. These tools ensure that connections are tightened according to engineering specifications and prevent loosening while a structure or piece of equipment is in use. Torque wrenches also prevent over-tightening, which can damage threads, shorten the lifespan of a connection or cause sudden structural failure. When choosing industrial torque wrenches and multipliers, you’ll need to consider project specifications, maneuverability and available or preferred power source. It’s important to remember that your initial purchase or rental is not only about procuring the product — it’s about the subsequent service. Every torque tool requires yearly calibration, so make sure the supplier you’re considering can provide annual calibration services, certificates and necessary repairs. Read on for what to consider when selecting a torque wrench for your application and some important safety reminders. Types of Industrial Torque Wrenches High-capacity torque wrenches can either be hydraulic, manual, electric, battery-powered, or pneumatic. Torque wrenches can be categorized further depending on their design and intended application. Manual (Click-Type) Torque Wrench These hand-operated tools can be set to deliver a specific amount of torque and will “click” once the desired torque has been reached. Click-type torque wrenches are best for jobs in tight spaces or with low visibility, since the wrench will give an audible cue once it achieves the preset torque. These tools have long lifespans, few parts or accessories and are fairly simple to use. Torque Multiplier For bolts that require a high amount of torque (or have been over-tightened), torque multipliers can deliver additional torque without requiring extra force on the part of the operator. Torque multipliers are essential for maintaining worker safety while tightening or loosening bolts by hand. Multipliers can also increase torque at small intervals at a very slow pace, reducing the risk of over-torquing or worker injury. Electric Torque Wrench With the ability to deliver more precise accuracy than an analogue tool, corded or battery-powered electric torque wrenches can be preset to a desired torque within ±3% to ±5% repeatable accuracy. If you choose to go untethered with a battery-powered torque wrench, have extra batteries or a charger on hand. If corded electric torque wrenches are your preference, be sure there is adequate clean power that allows you to safely reach your work area. This includes the proper generators (no welding generators or boom lifts) and/or properly installed spider boxes that output the correct power for the tools. If extension cords are necessary, anything longer than 150 ft. is not recommended. Hydraulic Torque Wrench When it comes to larger jobs, hydraulic torque wrenches are able to deliver over 25,000 ft.-lbs. of torque. They come in square-drive or low-profile designs called cassettes, which consist of the cassette and drive unit. Hydraulic wrenches themselves are quite light, but are accompanied by heavy systems that can carry a high price tag. Hydraulic systems include pumps and a stiff hose that can be difficult to move. Hydraulic torque wrenches also carry safety concerns related to pinch hazards and hydraulic fluid leaks, and should only be used by trained operators. Pneumatic Torque Wrench Like hydraulic tools, pneumatic torque wrenches can deliver much higher torque than a manual or electric wrench, but require additional equipment like an air hose and compressor. Torque Wrench Considerations The type and model of torque wrench you choose depends on your specific use case. Some considerations are fairly straightforward — torque range, size, power source — while some are often overlooked during the buying or rental process. Here is a list of questions to consider while making your torque tool selection:

Torque Wrench Safety Tips Be sure that all operators are briefed on safe handling and precautions before using any high-capacity torque tools. Here are some general safety guidelines to keep in mind:

Read the full article from GWY here. This Safety Flash was contributed by Don Laro, Sales and Marketing Manager for GWY, in cooperation with SEAA’s Safety & Education Committee. It’s designed to keep members informed about ongoing safety issues and to provide suggestions for reducing risk. Best practices are gathered from a variety of sources. They may be more or less stringent than individual corporate policies and are not intended to be an official recommendation from SEAA. Always get approval and direction from your company officers on any new practice or procedure as these best practices may not work for all situations. Everyone benefits when a worker avoids injury. Submit your ideas for Safety Flash to [email protected]. The 10th Annual National Safety Stand-Down to Prevent Falls in Construction will take place May 1-5, 2023. This initiative from OSHA helps to raise awareness on fall hazards in an effort to reduce fall fatalities and injuries. In 2021, there were 17 fatalities in the structural steel and precast concrete contractors’ sector and 11 of them were due to a fall, slip or trip, according to data from the Bureau of Labor Statistics.

“In the first three quarters of FY 2022, OSHA conducted over 9,700 inspections in the construction industry, of which 47% identified fall hazards with over $34 million in penalties issued for serious and willful violations in fall protection,” said Patrick Kapust, deputy director of OSHA’s Directorate of Enforcement Programs said in an interview about OSHA’s 2022 Top 10 Citations list. The list shows that OSHA cited 5,260 violations for Fall Protection-General Requirements in 2022, making it the number one most frequently cited workplace safety standard for the 12th year in a row. Fall Protection- Training Requirements also made the list as number eight. Four of the top ten citations are related to working as height which is why OSHA encourages employers to participate in the initiative by hold Safety Stand Down meetings the first week of May. Companies can conduct a Safety Stand-Down by taking a break to have a toolbox talk or another safety activity like conducting safety equipment inspections, developing rescue plans, or discussing job specific hazards. It can also be an opportunity for employees to talk to management about falls and other job hazards they see. In support of the National Safety Stand-Down, SEAA has created a Safety Stand Down page with lots of resources. Our downloadable posters are available for free to the public. The new poster for the 2023 Safety Stand Down, How to Make JSA’s Intentional, provides suggestions on how to complete a job safety analysis and getting the whole team involved in order to keep safety at the forefront of the job. Additional resources provide insight into related topics, such as fall prevention for loading and unloading trailers, wind hazards on elevated work platforms, protecting retractable lifelines from arcing damage, and more. Visit the Safety Stand Down Resources page for best practices. Resources: Census of Fatal Occupation Injuries Summary, 2021 OSHA’s Top 10 Citations of 2022 Injuries, Illnesses, and Fatalities, 2021. NAISC code 23812 This Safety Flash was contributed in cooperation with SEAA’s Safety Committee. It is designed to keep members informed about ongoing safety issues and to provide suggestions for reducing risk. Best practices are gathered from a variety of sources. They may be more or less stringent than individual corporate policies and are not intended to be an official recommendation from SEAA. Always get approval and direction from your company officers on any new practice or procedure as these best practices may not work for all situations. Everyone benefits when a worker avoids injury. Submit your ideas for Safety Flash to [email protected]. |

RSS Feed

RSS Feed