October 2013Click any article link:

SEAA Board Meeting October 17, Annual Golf Tournament October 18 - back to top

|

|

On October 4, 2013 Buckner’s spacious, high-ceilinged home office was flooded with over 150 visitors who came to experience Steel Day. Steel Day is an annual event sponsored by the American Institute of Steel Construction (AISC) to celebrate the contributions of the structural steel industry to sustainable building in America. This year Buckner Companies, based in Graham, NC, hosted its 5th Steel Day event with the aim of reaching out to students, teachers, customers, engineers, fellow businesses and community stakeholders to showcase the accomplishments and vision of the industry.

Student turnout was at an all-time high for this year’s Steel Day, with over 100 high-school and university students from 6 different schools in attendance. “We are excited to bring fresh, young minds into this industry and company,” emphasized Doug Williams, Buckner’s CEO and President, in his opening address. “As iron work grows and changes we need to have hardworking, creative people who are looking towards the future working in this company.” The day’s activities included a tour of the office, presentations by the Buckner team on various aspects of the company’s operations, a crane demonstration, a home-cooked lunch, and special sessions led by AISC and the NC Department of Labor.

The presentations highlighted the excitement and accessibility of steel work and allowed the students, many of whom visited from technical schools and career classes, to understand how their skills and interests might fit into the industry. “Are you creative and good at problem-solving, math and physics?” asked Jim Jatho, Buckner Heavy Lift’s lift planner, “Then you might be able to do what I do as a lift planner. It’s incredibly rewarding to see how all your plans and hard work are executed on the job site.” Mark Goodwillie, Buckner’s director of training, shared about Buckner’s certified apprenticeship program, which allows young workers to be paired with mentors and move up through the ranks of responsibility and experience over a period of 3 to 5 years. “We have recognized that nationwide our construction workforce is aging out and not enough is being done to attract and train young people who may want to enter our industry,” said Eddie Williams, the Chairman of Buckner’s Board. “Steel Day provided us with the opportunity to give young people a glance at what we do and inform them of the many job opportunities in steel. Buckner is committed to a full-scale Apprenticeship and Craft Training program.”

Added Williams, “Steel Day provided us with the opportunity to give young people a glance at what we do and inform them of the many job opportunities in steel.”

Lunch served as an opportunity for networking with Buckner staff and the numerous professionals from the steel industry who attended, as well as a chance to experience the company’s culture through food made by the staff and their families. Out on the yard, amidst dozens of red and yellow crane booms, trucks and other machinery, Steel Day visitors had the chance to observe and participate in a crane demonstration. Buckner’s mechanics and crane operators had assembled a Manitowoc 777 crawler crane and lifted a 50,000-pound motor for the on-looking crowd. Interested students had the opportunity to experience the crane operator’s point of view by sitting up in the crane and learning the major controls.

As students loaded into their buses and company representatives packed up their brochures and briefcases, there was a tangible energy in the air. Throughout the day, many speakers had voiced the sentiment that it’s exciting to drive by and see something you had a part in building, something that may be around longer than you. But not everything you build is visible. Steel Day 2013 built excitement, interest, knowledge and personal connections that will contribute to a more robust, sustainable and innovative industry, and as the office emptied out last Friday afternoon, nothing looked visibly different than it had before, but you could feel what had been built that day.

INDUSTRY |

||||||||||||||||||||||||||||

Cast Your Vote for the 2013 IC Top Lift - back to top

|

Entry 1: Building bridges EQUIPMENT USER: Riga Mainz Lifting services specialist Riga Mainz lifted a steel bridge over the A6 freeway in Germany. The 265-ton bridge was 70 meters long. A 500-ton capacity Terex CC 2500-1 lattice boom crawler crane was used for the main lift. The crane was assembled with a 54-meter main boom, 30-meter superlift mast and a 200-ton superlift counterweight. |

|

Entry 2: Identical lifting EQUIPMENT USER: Schmidbauer German crane and transport contractor Schmidbauer coordinated a 600-ton lift of an upper section of a jacket structure for the Borkum West II offshore wind park. The lift was carried out at the ABC-Halbinsel offshore terminal in Bremerhaven, Germany using two 750-ton capacity Liebherr LR 1750 crawler cranes. |

|

Entry 3: Power tower EQUIPMENT USER: XCMG An XCMG model XGC88000, 4,000-ton capacity level crawler crane was used to lift a propylene tower weighing 1,680 tons in Yantai, at the Wanhua Industrial Park, China. The tower was 118 meters tall and 14.4 meters in diameter. The XGC88000 had 108 meters of heavy boom and 33-meter fixed jib. A 1,000-ton capacity XCMG XGW1100 was used for tailing. |

|

Entry 4: Working giant EQUIPMENT USER: Sarens The 3,200-ton capacity Sarens SGC-120 super heavy lift ring crane named Big Benny was used to carry out a 1,300-ton lift at the Cosco Qidong shipyard on the Yellow Sea Coast, Shanghai, China. The components from the Octabuoy offshore platform were lifted at 30 meters radius. |

|

Entry 5: Coastal conditions EQUIPMENT USER: Sonamet A Manitowoc 18000 and a Manitowoc 16000, along with a third support crane, were used to lift a main deck from an offshore rig weighing 550 tons (498 tons US) at a specialized fabrication yard in Lobito, Angola. The cranes are owned by yard operator Sonamet, a joint venture between Subsea 7 and Sonangol. |

|

Entry 6: Tandem lifting EQUIPMENT USER: Tiong Woon Crane rental company Tiong Woon in Singapore used a 1,600-ton capacity Terex CC 8800-1 lattice boom crawler crane and a 2,400-ton capacity, 120-meter tall tower lift system in tandem to lift a xylene splitter column weighing 1,147 tons. The lift was carried out at Jurong Aromatics Corporation’s (JAC) complex at Jurong Island, Singapore. |

|

Entry 7: Confined spaces EQUIPMENT USER: Felbermayr Crane service provider Felbermayr lifted two large pipes inside the Šoštanj power plant, Slovenia, using a Terex AC 1000, from crane rental company Wasel and a 500-ton capacity assist crane. The AC 1000 had a counterweight of 108 tons. The pipes were raised to a height of 78 m. |

|

Entry 8: Brewery vessels EQUIPMENT USER: CPL Transport Services A 250-ton capacity Liebherr LTM 1250 and a 200-ton wheeled mobile telescopic crane from John Sutch Crane Hire lifted brewery vessels in tandem off a ship at Salford Quays in Manchester, UK. The vessels weighed 33 tons each and measured 28.5 meters long and 6 meters wide. The vessels were part of a refurbishment project at The Royal Brewery in Manchester. |

|

Entry 9: US super launch EQUIPMENT USER: Mammoet A Mammoet PTC 140 DS with a capacity of 3,200 tons lifted the first spar section for a new offshore platform going to the Gulf of Mexico. The piece weighed 816 tons and was lifted at a radius of 69 meters. Gulf Marine Fabricators (GMF) was the main contractor for the project. |

|

Entry 10: Lifeboat lifting EQUIPMENT USER: BKL German crane rental house BKL used a pair of Liebherr wheeled mobile cranes to move a 1950’s lifeboat onto a new foundation at a museum in Munich. The lift was performed in tandem using an LTM 1200-5.1 and an LTM 1250-6.1. A total weight of around 62 tons was moved. |

To register your vote, please click here or e-mail [email protected], including your name, your company's name, along with your choice. Deadline is October 31, 2013.

![]()

Liebherr Achieves Record Panel Lift - back to top

|

Liebherr LR 1300 crawler crane - Using a LR 1300 crawler crane, Liebherr set a world record for lifting the widest tilt-up panel in history at the York Preparatory Academy in Rock Hill, SC. The 27-meter panel, more than 9 meters tall and weighing 60 tons, was lifted by Citadel Contractors, a company specializing in tilt-up construction. Built at Liebherr-Werk Nenzing in Austria, the 300-ton capacity crawler has a maximum boom length of 172 meters when configured with a luffing jib. Citadel vice president Jason Swagert commented, “The operator loves the crane due to its ease of operation, and all important machine data can be accessed from our office via the onboard LiDAT system. The winches have higher line pull and are faster than other machines in this class – which makes it also the perfect machine for us for hanging steel.” You can read the full story on this record lift in the September, 2013 issue of American Cranes & Transport magazine.

|

For more information: http://steeljoist.org/publications-1

![]()

Latest ALH Toplist Covers Four Areas - back to top

|

Each year, Access, Lift & Handlers produces four toplists that rank North America’s telehandler, aerial and mast-climbing rental companies. The fourth toplist, scaffolding, ranks erecting and dismantling companies across North America. These lists provide an in-depth look into the North American access and telehandler markets, giving readers an analysis of market conditions. This special 2012 ALH toplist combines all four access and material handling areas with extended commentary and examination. ALH has fleshed out each toplist by providing additional background information on every company listed and ranked. The report is in English and is available for $80.

|

![]()

Cologne Cathedral Scaffolding Removal Proves Challenging - back to top

|

Dismantling two hanging scaffold structures from the north tower of Cologne Cathedral in Germany may seem fairly straightforward but presented several challenges. To carry out the lifts with the crane erected on the station forecourt at Cologne Central Train Station meant the operators could only assemble the boom at night. Technical manager of Wasel in Germany, Jürgen Oprée said, "In the run-up to this job, the assembly gave us some headaches. We had to consider station evacuation plans in our assembly schedules and also had to keep the escape and rescue routes free at all times. As well as all this, we were given a very tight time window for the set-up work." Further difficulties presented to Wasel during the project included a small assembly site of 90 meters, a result of which was that the boom had to be assembled in a suspended position. In total it took eight hours to configure the basic crane with supports, telescopic boom guys and a telescopic boom extension, including pivot section and ballast, a company spokesperson said.

During the lifts the scaffold sections were lifted between the cathedral towers and positioned in front of the main entrance of the cathedral. A Liebherr LTM 1070-4.2 helped with the final positioning of the sections. One of the scaffold structures was at a height of 100 meters. To carry out the tasks, a Liebherr LTM 1750-9.1 configured with a maximum hook height of 154 meters was used. One of the largest pieces of scaffolding was removed in three sections, according to a company spokesperson. Once the sections were separated, the LTM 1750-9.1 was able to lift the scaffold off the cathedral. The sections measured 7 meters wide and 33 meters high. In total, the task took four hours. |

![]()

Make Your Thoughts Known—Complete the Rental Confidence Survey - back to top

International Rental News (IRN) is conducting its annual Rental Confidence Survey, looking at levels of confidence in the equipment rental industry worldwide. The publication’s editor requests your response, using the survey links shown below. The survey should take only a few minutes to complete.

All information received is treated in the strictest confidence and is averaged to ensure anonymity. The results of the survey will be published in the November-December issue of International Rental News (IRN).

PLEASE CLICK THE LINK BELOW TO COMPLETE THE SURVEY

ENGLISH - https://www.surveymonkey.com/s/5399VMX

SPANISH - https://www.surveymonkey.com/s/KHWS3BJ

![]()

Steel Erection Bid Wizard Has Been Updated - back to top

On the market since January, 2013 Steel Erection Bid Wizard now has a demo version available. Vince Hughes explains, “If you have been curious how the Steel Erection Bid Wizard works, you can now try it in REAL TIME.” A recently released video shows how the Steel Erection Bid Wizard integrates with On Screen Take Off. With these two programs tied together offers a double benefit for steel erectors.

Use this link to request a free demo and the video:

http://steelestimatingsolutions.com

For questions or more information, contact:

Vince Hughes

505-249-2390

http://steelerectionbidwizard.com

![]()

Mantall Offers Redesigned Scissor Lift - back to top

|

Mantall will feature its HZ160D self-propelled articulated boom with auto-leveling technology at this year’s BICES exhibition in Beijing, China. The redesigned machine features a hollow chassis with a counterweight added to maintain stability, reducing the overall weight of the machine. It is well-suited to rough terrain with a maximum gradeability of 45%. Mantall will also display the XDW180 self-propelled scissor lift. With an 18-meter working height, the machine features a wide aerial work platform, four-wheel drive, and a diagnostics system to pinpoint maintenance issues. A rough terrain model with a working height of 14 meters, the XD140 RT includes a tilt level sensor and proportional controls. A record 1,500 exhibitors are expected to attend the BICES exhibition, which takes place from 15 to 18 October at the Jiu Hua International Exhibition Center in Beijing.

|

TRAINING |

||

No Train, No Gain! - back to top

|

|

Do you sometimes wish your managers and field crews were as good as you? Do they often struggle or fail to do things the way you want them done? Are your people as efficient and productive as they should be? Do your employees sit and wait for their boss to make simple decisions for them? Or, do your people constantly improve, try new ways to do things, and pro-actively make changes and master new tasks?

Human nature is to stay put and do things the same way as they have before. For example, how do you drive to work? The same way every day! People don’t like to change and, therefore, won’t try new ideas on their own unless they have no other choices. Improvement requires people to change. Most people want to do better, learn new things and grow. Training is the best method to encourage and make your people change and improve.

Are you too busy to train?

As construction companies grow, the owner takes on more work than he or she can handle alone. Therefore he or she hires some help to assist. Then as the crew grows and daily job pressures mount, the owner has difficulty finding good help to delegate responsibility to. They know they should train their people but don’t take the time. They become too busy to train and be at every jobsite all the time. What should they do?

Most continue to try and make all important decisions themselves and control everything. This never works as employees are held back and not allowed to grow. This causes field productivity to decrease and jobs costs to increase. And then, good employees leave for better opportunities. What’s your decision regarding investing in training?

Productivity in construction is at an all-time low compared to other industries. The average construction field worker only averages between four to five hours per day doing productive work. The other lost hours are spent waiting for their boss to show or tell them what to do, looking busy, correcting other’s mistakes, or working with the wrong tools or equipment.

Most small- and medium-size construction companies don’t have formal training programs. Consider the old method of distributing project information via blueprints versus today’s laptop computers, tablets, e-mail, and project websites. In today’s high-tech, high-speed business environment, people need to learn and improve just to stay relevant. Maybe your firm is too busy to train because you expect people to learn in a vacuum, or by the trial and error method, or from their previous boss at their last company.

People want to make meaningful contributions on the job. But if they don’t get the training and tools they need, they won’t accept responsibility for the quality and productivity of work they do and won’t grow into productive team players.

Training involves doing!

You can’t afford not to train. The first decision to start an effective company training program is to do it during regular working hours as a mandatory priority for everyone. Dedicate at least 30 minutes to training employees every week. This only amounts to 2.5 percent of your total payroll cost. An organized training program will improve your bottom-line significantly more than 2.5%.

Determine the 25 most important weekly training topics each employee type needs to know. For example, field concrete workers need to know how to form a building slab properly, where to install slab expansion joints, how to install steel embeds and anchor bolts, and how to fill out a timecard properly. Design learning sessions for each area and repeat them every 6 months to reinforce the basics.

Conduct training sessions in an interactive format versus the old classroom style of teaching where the teacher only tells the people what to do. Think coaching versus teaching and telling. Coaches explain, use examples, and get people doing exercises to encourage real learning. In group settings, select different people to lead your weekly training sessions, so everyone gets a chance to teach and be responsible for an area of workmanship. Assign topics to individuals based on their experiences and skills. Get people to stand up, participate, use tools, install materials, use equipment, and do it until they get it right.

Work together to learn together!

Offsite seminars and workshops can also be excellent training opportunities. But make sure your training programs offer more than listening to instructors. Good training involves coaching, interaction, doing, and feedback. As a professional speaker and trainer at several company meetings every year, I see lots of bad examples of training programs where the agenda includes training sessions, but no real learning happens. Some companies try to do all their training at one big annual meeting for their entire staff. The audience watches boring technical presentations or listens to a company manager read information to the group. The audience doesn’t participate in activities or provide input, and therefore doesn’t learn how to implement any new skills being taught. They sit there, listen, and try to stay awake. And then, back on the job the next day, they continue to do their job exactly as they did before.

I also speak at a lot of great annual training meetings and conventions where effective learning does takes place. Meetings can be an excellent training opportunity if organized properly and then combined with effective ongoing weekly companywide training sessions. To round out and improve your annual training, be sure to include interactive training, feedback, fun, motivation, rewards, excitement, and recognition.

To get started, form a company improvement committee that meets monthly. Task them with the responsibility to design your ongoing company training program. Let them develop your training ladder, topics, schedule, and format for implementation. By involving many of your key employees in this effort, everyone will get onboard and make this program a success. To help you set your training goals and targets, email [email protected] to get a “Write Winning Targets & Goals” e-book.

Keynote speaker for SEAA’s 2014 convention, George Hedley works with contractors to build profitable growing companies. He is a professional business coach, popular speaker and best-selling author of “Get Your Business To Work!” available online at www.HardhatPresentations.com. To sign-up for his free e-newsletter, join his next webinar, be part of a BIZCOACH program, or get a $100 discount coupon for online classes at www.HardhatBizSchool.com, e-mail [email protected]

![]()

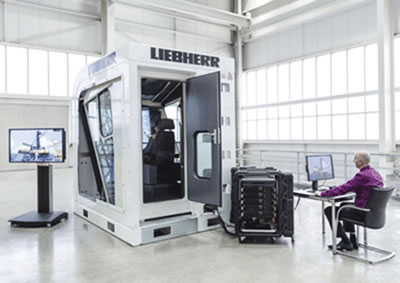

A Liebherr simulator |

Industry statistics underscore the connection between increased training and reduced fatalities on construction sites. The question is how to provide training in a cost-effective way. Now simulation training programs offer a solution with many benefits. Simon Hogg, application consultant at

TenStar Simulation, a manufacturer of training simulators for the construction industry, explains why, “Learning to operate a crane for the first time can be a daunting prospect, as well as costly exercise for the training provider. Through simulator training students learn terminology, control familiarization, hand-eye co-ordination skills and they can return to the simulators and practice certain areas they may feel weaker in. The most significant benefit by far is that mistakes can be made on a simulator, which is not an option on an actual site.”

While simulators are not a replacement for training on an actual machine, they can be used to train a whole team, not just an individual, with minimal costs and risks to health and safety.

Sebastien Loze, director of marketing and partner sales at CM Labs, manufacturer of

Vortex Simulators , says, “Crane simulator training is not just about training the operator, it is [about making it] possible to teach the whole lift crew. Teamwork cannot be taught in the classroom but, with a simulated training environment that incorporates multi-role-playing [including lift planning, lifting and reviewing], the operator, signalman and rigger can all be trained together and take these skills out to the real job.”

Other Benefits of Simulation Training

- For the cost of one 28-ton hydraulic excavator, you can have up to 20 virtual machines by using Tenstar's simulator program. This makes the return on investment of a simulator substantially higher than that of a real machine.

- Electricity cost of a simulator is only a fraction of the fuel consumption of a real machine. In addition, machine wear and tear can be decreased significantly if operators are allowed to build up skill and practice in a simulator environment before practicing in a real machine. All keeping operating costs down.

- Simulation can include harsh environmental conditions, such as snowfall, heavy winds, torrential rain and high waves. This allows both experienced operators and trainees to practice operating in challenging conditions and, thanks to the virtual environment, to eliminate damage to crane equipment and injuries to personnel.”

- Training can apply not only to new employees but also experienced operators who need familiarization with newer equipment.

- Simulators can include real seats and controls, authentic worksites and sounds [including weather], and a head-tracking system for precise points of view. A 3-degree-of-freedom motion platform replicates the motion and vibration experienced by the operator while travelling and lifting.

- An instructor’s console allows trainers to introduce unexpected events such as mechanical and hydraulic problems and sling breaks.

- All progress is monitored and training sessions collect information related to the number of collisions and spills, loading violations, time spent in rough handling of crane, objects moved, and more.

- Operators can practice standard tests such as the National Commission for the Certification of Operators [NCCCO] tests using different types and sizes of cranes or train and prepare for NCCA-accredited Crane Institute Certification (CIC) exams.

TenStar Simulation includes tower crane, truck mounted crane and timber truck crane simulators. The tower crane simulator has 11 exercises ranging from basic lifting to pouring concrete. The truck mounted crane simulator has a further 24 exercises. Throughout these exercises students are notified with visual warnings as they progress through the tasks. This is accompanied by a report to assess the students’ progress and performance and to identify any problem areas which need more training.

SAFETY |

|||||||||||||||||||||||||||||||||||||||||||||

New Personal Fall Limiter Available from Safway - back to top

|

The new Miller TurboLite Personal Fall Limiter (PFL) |

Safway, an access and scaffolding company, worked with safety equipment manufacturer Honeywell to develop a new, lightweight version of the Miller TurboLite Personal Fall Limiter (PFL).

“We turned to Honeywell/Miller to help us develop and engineer fall protection equipment designed specifically for our industry,” said Safway Group president and CEO Bill Hayes. “This is part of our 100% fall protection policy requiring all of our employees who are working at heights to wear protective gear. We want to provide our employees with the best possible fall protection equipment. The Miller TurboLite PFL, combined with the Miller Aircore harness and other Honeywell fall protection products, gives our workers more flexibility, while keeping them secure and properly tied off. ”

Specifically designed for use in the scaffold and access service industries, the new Miller TurboLite PFL is available in a six-foot (1.8 m) and a new nine-foot (2.7 m) model, providing complete range of motion, while workers maintain full tie-off requirements. In addition, a self-retracting lifeline halts any fast and unexpected movements, stopping any falls within inches instead of feet.

The Miller TurboLite PFL is also equipped with a radio frequency indicator (RFI) feature so that users can track the safety equipment, identify to whom and when the equipment was issued, and when it was last inspected.

“Workers are going to be in compliance if the equipment that they use is designed to fit their needs,” said Jack Boss, president of Honeywell Safety Products. “This is in line with our mission to work with customers on their application-specific safety equipment needs, which in turn leads to innovation and improved worker safety. Through work with companies like Safway Group, Honeywell Safety Products is becoming the reference leader across personal protective equipment categories.”

Safway has reduced its recordable injury rate among employees by more than 50% over the past year and by more than 70% in U.S. refinery/petroleum and power markets because of these safety improvement measures.

![]()

Fall Protection Retains Top Spot on List of OSHA's Most Frequent Citations - back to top

The top four standards on the 2013 list are the exact same ones that made up the top four in fiscal year 2012, and in the same order.

This year, however, no OSHA official was on hand at the 2013 National Safety Congress and Expo for the unveiling of the top 10 list because of the federal government shutdown.

"I've had the privilege of hosting this presentation the last five years, and every year we've had an official from OSHA here to talk with you about these top 10 violations and how they relate to workplace hazards and what they mean to workplace safety," Kyle Morrison, senior associate editor for the National Safety Council's Safety and Health magazine, told a large crowd on the expo floor at the McCormick Place in Chicago.

In a brief presentation, Morrison unveiled the preliminary figures for the top 10 most frequently cited OSHA standards in fiscal year 2013:

|

Rank |

Hazard |

Standard |

# of Violations |

|

1 |

Fall protection |

(1926.501) |

8,241 |

|

2 |

Hazard communication |

(1910.1200) |

6,156 |

|

3 |

Scaffolding |

(1926.451) |

5,423 |

|

4 |

Respiratory protection |

(1910.134) |

3,879 |

|

5 |

Electrical, wiring methods |

(1910.305) |

3,452 |

|

6 |

Powered industrial trucks |

(1910.178) |

3,340 |

|

7 |

Ladders |

(1926.1053) |

3,311 |

|

8 |

Lockout/tagout |

(1910.147) |

3,254 |

|

9 |

Electrical, general requirements |

(1910.303) |

2,745 |

|

10 |

Machine guarding |

(1910.212) |

2,701 |

Although there hasn't been much deviation in the list, Morrison said he expects OSHA's recently revised hazard-communication standard to be the focus of attention in the coming years. OSHA revised the hazcom standard in March of 2012 to align the rule with the United Nations' global chemical-labeling system. The deadline is December 1, 2013 for employers to train their workers on the rule's new labeling elements as well as the new standardized format for safety-data sheets.

Morrison noted that the shutdown forces OSHA to trim its full-time work force from 2,300 to 236 employees. In a recent memo, OSHA Administrator David Michaels indicated that the agency would cease most enforcement activities, except for responses to fatalities, catastrophes and complaints regarding life-threatening work conditions.

RSS Feed

RSS Feed