|

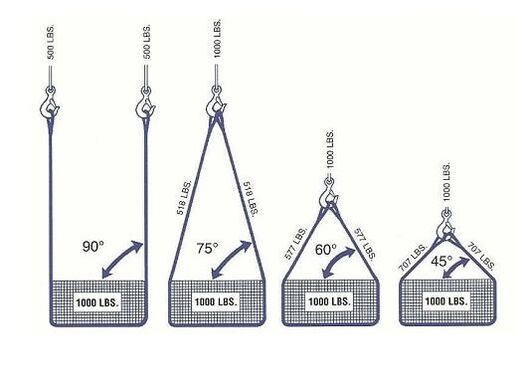

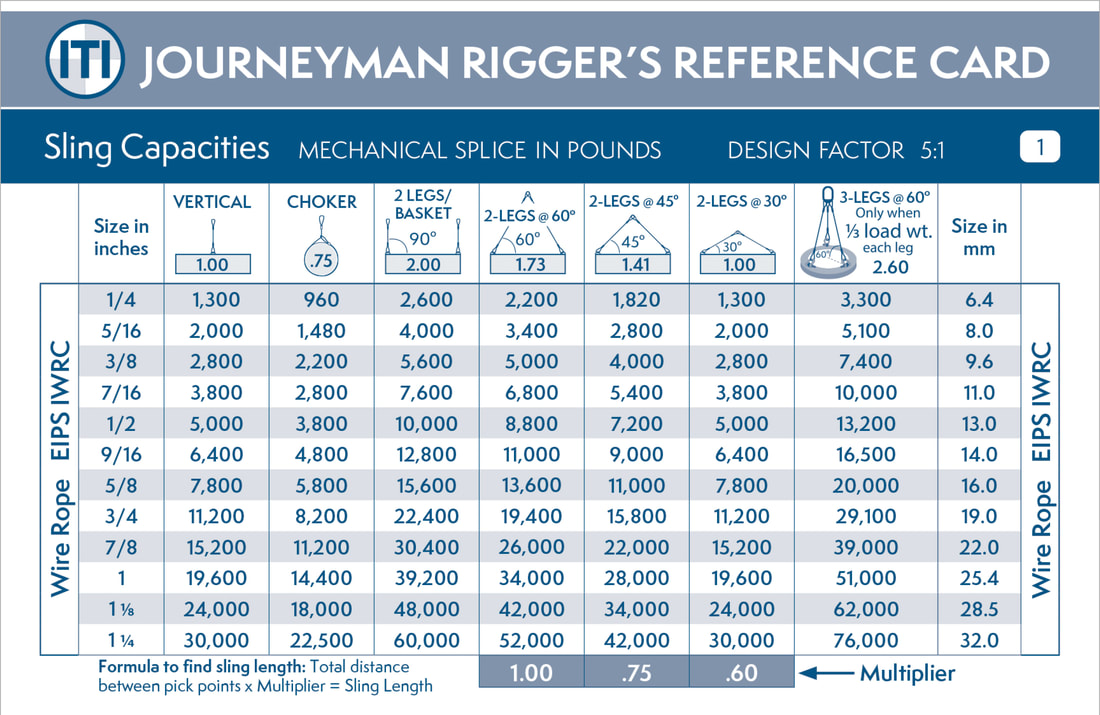

Pop Quiz: What’s the total sling capacity of two ½” EIPS/IWRC wire rope slings that are used in a double wrap choke at 45 degrees? The answer may surprise you. Failure to properly account for sling tension is the most common rigging mistake I’ve seen construction professionals make over the years. Sling tension occurs when the slings are rigged at an angle; this directly affects capacity. The same misunderstanding of sling angle on capacity often happens when basket hitches are rigged to a single attachment point, whether the sling is vertical or at an angle from the center gravity. Many riggers simply believe that the lifting capacity is doubled because of the assigned multiplier of 2.00. Keep reading to find solutions to these scenarios and to learn about handy references every rigger should have. Best Practices Once riggers understand the principles, a handy reference card, like the Journeyman Rigger Reference Card from Industrial Training International, is a valuable tool. Here’s why a basket hitch’s capacity isn’t doubled if lifting from the same attachment point. When using slings in a basket hitch to a single attachment point, the sling angle creates additional forces that need to be accounted for. The only scenario where a basket hitch achieves twice the lifting capacity is when the carrying legs of the slings are at 90 degrees from horizontal and straight up and down, achieved by rigging to two attachments points. (Far left illustration.) But when the legs of the basket hitch connect at an angle, as shown in the three illustrations on the right, additional forces are applied to the slings. In this scenario, there are actually two sling angles to account for. The first is at the sling’s eyes to the attachment point; the second is dependent on the distance the center of gravity is from the attachment point (determined by the sling length). The mistake occurs when the rigger takes the basketed reference capacity for face value and doesn’t properly assess the angles that are in play. Here’s another example. In this scenario, if the rigger were to select two 5/8" EIPS IWRC slings to lift this load and not properly account for sling angles they’d believe that the rigging is capable of lifting 31,200 lbs. in tandem. But if the rigger accounted for 60-degree sling angles, created by attaching to a single attachment, the rigger would know the actual lifting capacity is 23,528 lbs. That’s a difference of 7,672 lbs! Here is the process for determining the lifting capacity. 1. Account for angle that is created by the sling eyes being attached to same attachment point. Do this by referencing the rigging capacity at that angle for the type of sling. (For EIPS IWRS that is 13,600 lbs.) 2. Identify the sling attachment point. In this case, it is not centered directly over the pick point of the load. Note the 60-degree reference column. 13,600 X 1.73 = 23,528 lbs. Answer to the Pop Quiz: What’s the total sling capacity of two ½” EIPS/IWRC wire rope slings that are used in a double wrap choke at 45 degrees? The answer may surprise you. Students in my training classes typically answer 7200 lbs. or 7600 lbs. These incorrect answers are often a result of the individual not receiving proper training on how to read and understand the Journeyman’s Rigger Reference Card. ½” EIPS IWRC wire rope sling in a choked configuration has a rated capacity of 3800 lbs. At 45 degrees we have a listed sling multiplier of 1.41. 3800 X 1.41 = 5358 combined rated lifting capacity. As you can see there is a significant difference in actual lifting capacity to an approximate capacity that can be mistakenly referenced with a lack of understanding on how to use the card. Resources

ITI Journeyman Rigger Reference Card Spanish Version ITI Journeyman Rigger Reference Card ITI Why Sling Angles Matter Ashley Sling Calculating Sling Angles LiftAll Affect of Angle of Lift on a Sling’s Capacity Crosby Sling Angles Best Practices This Safety Flash was contributed by Scott Seppers, Training Consultant, Trivent Safety Consulting in cooperation with SEAA’s Safety Committee. It is designed to keep members informed about ongoing safety issues and to provide suggestions for reducing risk. Best practices are gathered from a variety of sources. They may be more or less stringent than individual corporate policies, and are not intended to be an official recommendation from SEAA. Always get approval and direction from your company officers on any new practice or procedure as these best practices may not work for all situations. Everyone benefits when a worker avoids injury. Submit your ideas for Safety Flash to [email protected] Comments are closed.

|

RSS Feed

RSS Feed