The ASME volume B30.9-2018: Slings revises the 2014 edition, and contains changes pertaining to wire-rope slings, starting with a new section on “Rigger Responsibilities.” Those changes include:

Early signs of wire rope sling failure can actually provide the user with a margin of safety. A wire sling needs to be discarded when it shows signs of:

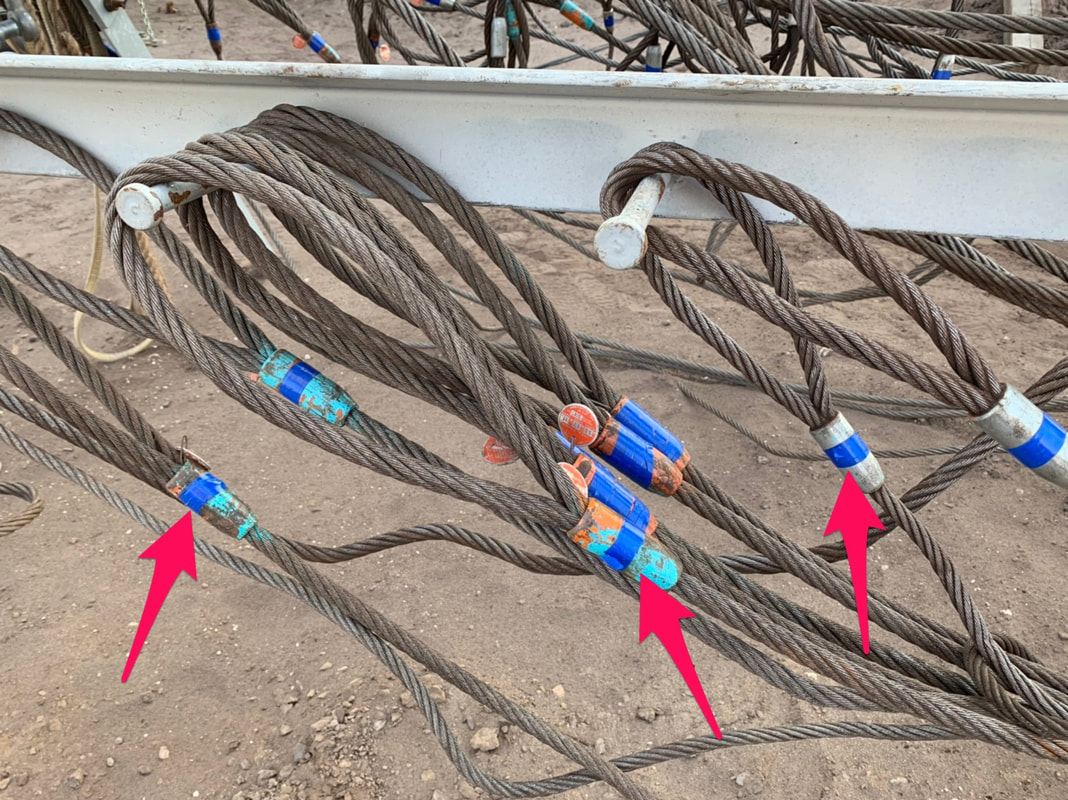

BEST PRACTICES The goal of a sling inspection is to evaluate remaining strength in a previously used sling to determine its suitability for continued use. Daily visual inspections, designed to detect serious damage or deterioration that would weaken the sling, are usually performed by the person using the sling daily. Obvious issues, such as broken wires, kinks, crushing, broken attachments, and severe corrosion, should be looked for. Any deterioration that could result in appreciable loss of original strength should be noted to determine if further use would result in a safety hazard. Train all employees in the safe use of rigging and proper rigging gear inspect inspection before each use. No more than three broken wires in a rope lay are allowed. Wire rope slings, like chain slings, must be cleaned prior to each inspection because they are subject to damage hidden by dirt or oil. In addition, they must be lubricated according to manufacturer's instructions. Lubrication prevents or reduces corrosion and wear due to friction and abrasion. Before applying any lubricant, however, the sling user should make certain that the sling is dry. Applying lubricant to a wet or damp sling traps moisture against the metal and hastens corrosion. Corrosion deteriorates wire rope. It may be indicated by pitting, but it is sometimes hard to detect. If a wire rope sling shows any sign of significant deterioration, that sling must be removed until it can be examined by a person who is qualified to determine the extent of the damage. Using rigging racks or storing slings in a Conex storage container is always a best practice. Using with the correct size of shackle while choking slings will prolong the life of the sling. Finally, a monthly inspection color code program will assure inspections are being performed. RESOURCES

Three industry standards provide the end-user with guidelines for inspection and criteria that warrants removal from service: OSHA 1926.251(c)(4)(iv) for Construction), OSHA 1910.184 for General Industry) and ASME B30.9. Read more at the ANSI Blog: ASME B30.9-2018: Slings OSHA’s wire rope rules can be found under Subpart Title: Materials Handling and Storage. This detailed blog post from Mazzella Companies outlines the specifics on how to inspect wire rope slings, when to discard slings, and how often to inspect them. This Safety Flash was contributed by Ed Valencia of MEMCO LLC, Culpeper, Virginia, in cooperation with SEAA’s Safety Committee. It is designed to keep members informed about ongoing safety issues and to provide suggestions for reducing risk. Best practices are gathered from a variety of sources. They may be more or less stringent than individual corporate policies, and are not intended to be an official recommendation from SEAA. Always get approval and direction from your company officers on any new practice or procedure as these best practices may not work for all situations. Everyone benefits when a worker avoids injury. Submit your ideas for Safety Flash to [email protected]. Comments are closed.

|

RSS Feed

RSS Feed